|

Titanium Nitride (TiN) is one of the most common PVD

hard coating in use today. TiN has an excellent combination of perform-ance properties,

attractive appearance, and safety (meets FDA requirements for surgi-cal tools

and implants as well as food con-tact applications) *

Benefits of TiN Coatings

- Wear resistance

- Maintains sharp edges or corners

-

Prevents galling or seizing

- Safe for surgical

devices and food

processing

- Decreases friction

-

Resists corrosion

- Withstands high temperatures

* Features of TiN Coatings

-

Lubricity

- Resistant to nearly all chemicals

- Heat resistant

-

Non-stick surface

- Non-toxic

-

Environmentally friendly process

- Physical

Vapor Deposition (PVD)

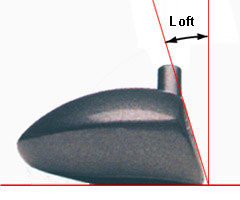

Golden_Eagle titanium

driver, 245cc, golden coating, 10.5 degree loft, 55 degree lie,

198 grams. |

|

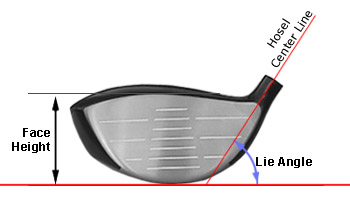

| LOFT(°) | 10.5 |  1 1 |

| LIE(°)

| 55 |  1 1 |

| WT.(g)

| 197 |  3 3 |

| Volume(cc)

| 250 | - | | Face

Heights | 2.0"(50mm) | - | | Hosel

I.D. | 0.335"(8.60mm)

Parallel | | Hosel

O.D. | 0.49"(12.50mm) | | Shafting

Depth | 1.41"(36mm) | | Face

Angle | -1° | | Materials

| 6Al-4V Titanium with

Golden-TiN Coating |

|